Prime

Factories operating at 55% capacity, says study

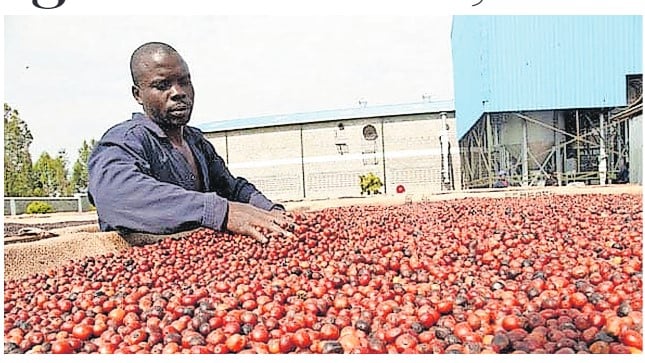

Many companies indicated in the study that they have almost half of the installed capacity unutilised. Photo / File

What you need to know:

- Large manufacturers deploy an average of 35.5 percent of installed capacity, while medium and small manufacturers deploy about 66.8 percent

At least 45.6 percent of manufacturing capacity remains unutilised due to low demand for locally produced products, high taxes, and competition from imported products, according to a study by Private Sector Foundation Uganda (PSFU).

The factors above are just part of a catalogue of issues responsible for redundant capacity, with the most affected being large manufacturers.

In details contained in an assessment of capacity utilisation in the manufacturing sector conducted among 199 members of Uganda Manufacturers Association (UMA), Uganda Small-Scale Industries Association, government and development partners, PSFU found that average capacity utilisation stands at 54.4 percent, which implies that almost half of Uganda’s industrial capacity remains redundant.

The study notes that the low capacity utilisation is more spread among large manufacturers, which deploy an average of just 35.5 percent of installed capacity, while medium and small manufacturers deploy 66.8 percent.

“There is a lot of redundant capacity among [manufacturers] where a lot of resources have been invested. Considering membership, capacity utilisation is much higher for Uganda Small-Scale Industries Association [member] firms compared to UMA [members],” the report reads in part.

Dr Julius Byaruhanga, the PSFU director of policy, yesterday said majority of sampled manufacturers had pointed to low demand for locally manufactured products as being responsible for the low capacity utilisation, possibly due to low purchasing power, among others.

“For most of our manufactured products, the aggregate local demand is very low. As a manufacturer, you cant produce goods to be kept in a store,” he said, noting that low demand has been worsened by competition presented by cheaply imported products.

The study, which seeks to establish the actual capacity of manufacturers, investigate constraints, and establish challenges experienced by companies in the provision of goods and services, found that lack of sufficient demand for locally manufactured products accounted for 56 percent for the low utilisation capacity, followed by competition (44 percent), high cost of inputs (42 percent) and taxes (41 percent).

Other factors, the study noted, include low participation by local companies in the supply of government products, low supply of raw materials, inadequate access to affordable financing, limited innovation, and use of outdated technology.

Therefore, Dr Byaruhanga said, there is need to have a deeper understanding of some of the issues captured in the study, so that government can formulate the right policy interventions and prescribe support mechanisms to raise capacity utilisation.

“There is need to implement relevant policies and actions to unlock the unutilised capacity,” he said.

Beyond this, the study recommends that although capitalising Uganda Development Bank is a remedy to credit challenges, UDB should be repurposed to focus on catalysing industrialisation by identifying priority sectors for interventions, as well as segment the finance and credit terrain to be inclusive to the needs of large, medium and small manufactures.

The study also recommends implementation of the 2017 EAC Act and strengthening of actions that handle violation of non-tariff barriers, strengthening of dispute resolution to counter unilateral actions that impede exports, as well as improve quality standards to support adoption and certification of standards of manufactured products for especially SMEs.