A farmer feeds his dairy cows with a mixed silage. However, agronomists say maize silage is a preferred and frequently used forage in dairy cow nutrition, mainly due to its high dry matter (DM) production, high DM content at one harvest, high net energy of lactation (NEL) concentration, and high milk yield. PHOTO/ABU LUBOWA

Maize silage is mainly used to feed all dairy cattle on the farm: growing animals, dry cows, and lactating cows. It contains protein, minerals, and sometimes the energy to meet the animal’s nutritional needs. Although it is occasionally used as the sole forage for dairy cattle, it is usually fed as a complimentary forage, such as alfalfa, which is high in crude protein but low in energy.

Maize silage produces more energy per acre compared to other crops. Therefore, corn silage serves as a high-energy forage for dairy cows. In addition, maize silage can efficiently recycle plant nutrients, especially large amounts of N and K.

A detailed plan for maize silage production is essential to an efficient cropping system. Crop planning should be based on forage dry matter requirements considering harvest, storage, feed losses, and agronomic factors such as field selection, hybrid selection, rotation, fertility, and weed control programmes.

A primary consideration for maize silage production is whether maize silage fields will be identified during the growing season or planning.

Fodder used to make silage should have a moisture content of 60 to 70 percent or dry matter in the range of 30 to 35 percent.

Production methods

Silage ensures the availability of fodder for livestock during the dry season. Silage also helps improve animal digestion and sustain milk production throughout the year.

Maize silage is a digestible and edible forage with consistent quality, high yield, and higher energy than other forages. Maize silage can be stored for about two years once produced because of the increased shelf life.

It is more nutritious than other feed options and improves farm productivity by significantly reducing production costs. Additional inoculants containing lactic acid-producing bacteria improve the fermentation process, retain valuable nutrients, reduce spoilage, increase milk yield and improve milk quality by increasing milk fat percentage and protein.

Weed and pest management

Weed and pest control strategies in maize for silage are similar to those in the maize for grain. Silage production is more sensitive than grain production to pests or other factors that reduce stand because maize plants have difficulty fully compensating for missing plants.

Poor weed control in corn can have several negative effects on silage. Where there is poor weed control, both forage yield and quality can be reduced, and many weed seeds can be incorporated into the compost.

Hybrid selection for silage production

Maize hybrids selected for silage production should have a high yield of quality silage. The productivity of hybrids can be obtained from silage performance tests. Select hybrids with a relative maturity of 10 days longer than full-season grain hybrids for your region to maximise corn silage yield potential.

These hybrids often have a yield advantage of two to four tonnes per acre over standard maturity hybrids. Later maturing hybrids are unsuitable where the crop may be harvested for grain, where early silage is desired, or where wet soils can interfere with harvest. The maturity range of hybrid varieties selected for a particular farm must be carefully considered.

Stephen Muvunyi feeds his Friesian cows with silage. Photos / George Katongole

What type of maize is used for producing silage?

Dual-purpose, leafy, and hybrids are the three main types of maize grown for silage on dairies today. Dual-purpose hybrids were designed for grain or high-quality corn silage production. As a result, dual-purpose hybrids generally have high grain yield potential and moderate fiber digestibility.

Silage production can be an economical source of nutrients for sheep and goats, especially on large farms where feeding can be mechanized. Maize silage consists of whole plants. Silage can also be made from fodder and small grain crops.

How long does it take to grow?

Silage harvest typically begins at about 50 percent kernel milk 42 to 47 days after silking. But remember that the timing of silage harvesting is dependent on achieving adequate moisture for the storage structure.

Silage for goats

Silage has been used in goat feed formulations for decades. It is best to contribute energy to the diet for the she goat. Large herds, 200 head or more, often use maize silage in rations fed into fence line feeding systems.

Maize silage is a fermented feedstuff that provides great flexibility in the she goat diet formulations during pregnancy and lactation. It is considered a very economical forage source for ruminant diets. Silage has been used in sheep feed formulations for decades.

It is combined with other types of forage, additional energy, or protein feed sources to meet the recommended nutritional requirements of the animals.

This type of silage has lower levels of protein, minerals, and vitamins when compared to higher-quality forages, such as alfalfa. Due to limitations in overall nutrient composition, maize silage is often combined with high-quality forage to meet nutrient requirements.

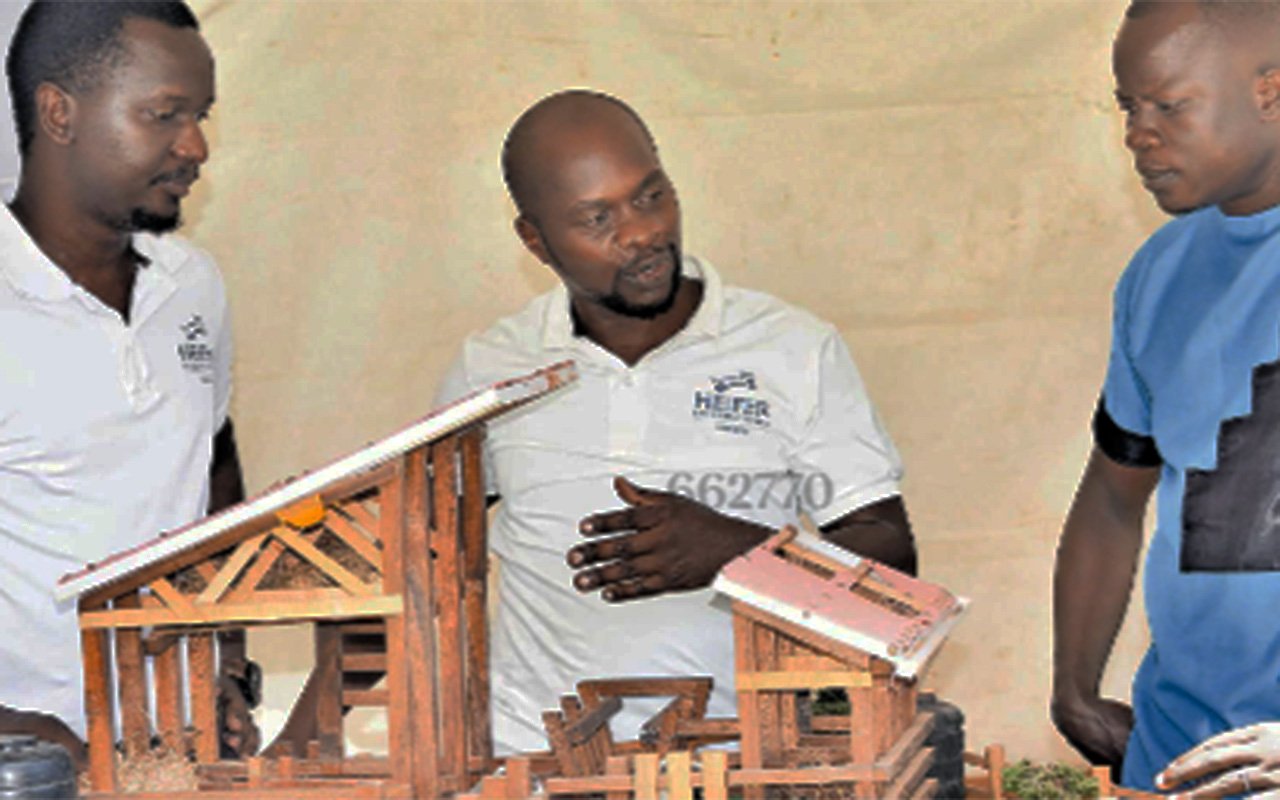

A group of farmers being trained on how to make silage. Feeds is one of the challenges faced by many livestock farmers in Uganda, therefore making hay and silage from things like potato vines is a welcome intervention. FILE PHOTO

Silage for cows

Maize silage is a preferred and frequently used forage in dairy cow nutrition, mainly due to its high dry matter (DM) production, high DM content at one harvest, high net energy of lactation (NEL) concentration, and high milk yield. Due to its ability to retain good properties. The primary objective of making maize silage is to preserve as much of the corn plant’s nutrients as possible, produce a feed acceptable to the cow, and minimise any risks associated with feeding the silage.

Maize silage is mainly used to feed all dairy cattle on the farm: growing animals, dry cows, and lactating cows. It contains protein, minerals, and sometimes the energy to meet the animal’s nutritional needs. Although it is occasionally used as the sole forage for dairy cattle, it is usually fed as a complimentary forage, such as alfalfa, which is high in crude protein but low in energy.

Feeding strategies vary based on animal age, production level, body condition, and other forages being fed if any. Because of the high grain content, corn silage feeding to high-producing cow’s strategy differs from other forages.

Harvesting

Silage that has been properly prepared should be green/yellow and have a mild, pleasant vinegary smell. If it is a dark brown colour or has another odour like a fruity, burnt smell, improper fermentation, or overheating has occurred. Understanding the fermentation process can help explain some of the problems in silage production.

Moisture content

Fermentation or pickling is done by bacteria that convert some of the sugars in the greens into lactic acid. These bacteria require the right conditions to thrive and carry out positive fermentation. One of these conditions is humidity. Maize silage should be fermented at 35 percent dry matter or 65 percent moisture to facilitate packing and promote the growth of desirable bacteria. When monitoring corn fields for silage, a rule of thumb is to consider a drying rate of 0.5 percent per day.

Fermentation When a corn plant is cut and placed in some storage facility, the cells of the corn plant are still alive. Microorganisms in the respiration and silage of these plant cells produce carbon dioxide and heat. It is called aerobic respiration because oxygen is used. As carbon dioxide levels rise and oxygen levels fall, this respiration slows to a halt, and anaerobic (without oxygen) fermentation begins.

In this process, beneficial bacteria primarily use soluble carbohydrates in the cells to produce lactic acid. Lactic acid causes a drop in pH. Fermentation will continue until enough lactic acid is produced to drop the pH to about 4.2, at which point all bacterial activity ceases. It usually occurs within three weeks after filling the silo. If low levels of lactic acid build up, butyric acid, a foul-smelling acid, is produced, and silage spoils.

Correct stage

Appropriate harvest time is one of the most important factors affecting the quality of maize production. In addition, the stage of maize maturity will affect the quality of the maize silage because of the nutrient and moisture content of the plants.

Kernel processing

Removing as much oxygen as possible from the forage fed is important to promote good fermentation. To accomplish this, the fodder is packed and compacted. If the chop length is too thick, it becomes difficult to pack and can cause spoilage and non-fermentation problems. Kernel processing unlocks the energetic potential of the starch in the corn kernel because the protective layer of the kernel is damaged, exposing the starch to microbial fermentation in the rumen. Processed corn silage should not contain whole kernels and no visible cob pieces.

Silage storage

After the first two steps, the next step is to seal the compressed hay with plastic to keep out oxygen. Mounds of silage are covered with large sheets of polyethylene (plastic) and weighted (usually with old tires) to ensure maximum compression. Bales, on the other hand, are covered with plastic wrap. In cases where silage has to be stored in a large pit, tractors and other machinery are usually driven over the grass pile until it is firm. If the silage is stored as bales, baling machines will be used to compress the hay.

Preservation techniques

After the fermentation process is complete and all the oxygen is used up, lactic acid bacteria begin to grow. These are the bacteria needed to make silage. They play a key role in converting plant sugars to lactic acid, which causes the pH to drop (the mixture becomes more acidic). Once the pH is around 4-5, the breakdown of sugars stops, and the hay is preserved until the silage is opened and exposed to oxygen.

However, if the pH is not low enough, a variety of bacteria will begin to ferment the silage, producing by-products (such as ammonia) that are bad for cows. Thus, the latter situation needs to be avoided at all costs. Specialising in harvesting and baling processes, we work best with farmers by sending a team of experts who will come to your farm, harvest, and pack the crop in the best possible conditions.