Prime

Tissue culture: An option for farmers to get clean banana planting materials

A typical smallholder banana farm in Uganda. With tissue culture, such farmers are able to have planting materials, free of disease and pests, which will help them increase production. File Photo.

What you need to know:

Pests and diseases are a significant challenge to farming in Uganda. This technology helps farmers to deal with such constraints.

As banana farmers are faced with devastating pests and diseases that affect their crop, the alternative option is disease-free plantlets developed through tissue culture. A number of privately run laboratories are developing these plantlets and availing them to farmers.

One of these is Nsigotec Tissue Culture Laboratory found in Kiteezi, an area outside Kampala, where farmers can access a number of matooke varieties ranging from Mpologoma, Nakabululu and Nakitende, among others.

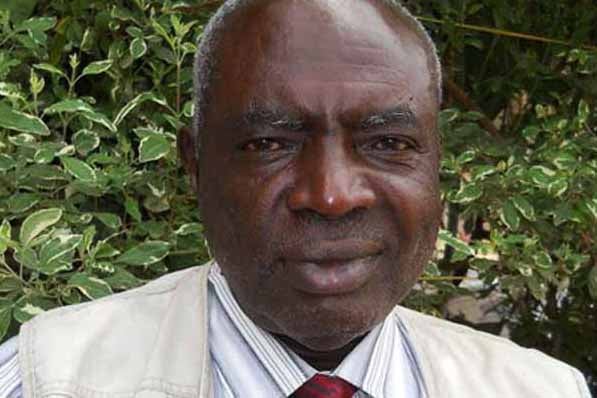

The proprietor, Arthur Makara, points out that tissue culture is a biotechnology technique used to breed planting material, which are free of pests and diseases.

Material

It is also a tool that can be used to multiply seedlings at a faster rate and in a less bulky package. However, there are challenges of ensuring cleanliness in the laboratory to avoid damage during the growth stages.

Before the breeding exercise starts, pieces of small suckers are acquired.

These must be fresh because this will help get the clean planting materials. The plant may end up aborting if the original material is not fresh.

Standards

Tissue culture is undertaken where high standards of sterility are enforced to ensure new plantlets are completely free of pests and disease agents like bacteria and fungi.

In the case of bananas, tissue culture effectively eliminates weevils and nematodes, bacterial diseases such as the Bacterial Xanthomonas Wilt and fungal diseases like Fusarium Wilt and Sigatoka. Tissue culture has been shown to bring down the cost of controlling foliar diseases by half.

In explaining the process of plant breeding using tissue culture, Makara said cleanliness starts with the sterilisation of the bottles where plants are grown in the media. This is done using an autoclave machine.

Nutrients

“The challenge we face as scientists is poor handling, failing to clean hands with ethanol which may eventually affect the growth of the plantlet. While in the lab we ensure that the leaves are split after three weeks to ensure smooth growth,” observes Makara.

From the inception, a number of plantlets germinate in the media and it is the duty of the laboratory technicians to split the plants by obtaining one plantlet using blades. In all, it takes about eight months from the time the breeding starts to when it is ready for the dispatch to farmers.

Just as plants in the soil get the nutrients such as potassium, magnesium and sodium, the same applies in tissue culture where these substances are contained in the media, which is a supporting nutrient to the plants while growth takes place in the laboratory.

Eliminated

Once the new banana plantlets sprout, they are nurtured in the laboratory for a couple of weeks or so before being taken to a greenhouse for further growth.

After two months and at 30cm high, the plantlets are ready for planting on-farm. In comparison with the conventional use of suckers, the technique dramatically speeds up the multiplication process.

The advantage is that from a single piece of a sucker, one is able to generate 300 plantlets and it is clean planting material, where the diseases would have been eliminated through the entire process of breeding.

Farmers are turning to tissue cultured banana plantlets especially with the prevalence of the banana bacterial wilt.

Get involved

Nsigotech sell each sucker between Shs1,000 and Shs1,500. Most of the clients are from Kiteezi and from Kasese and Mpigi districts.

Small scale farmers may not purchase them in large numbers but commercial farmers can afford to buy on a large scale. Some farmers organise themselves in groups to purchase and share the plantlets accordingly. A case in point is a women farmer group in Nagoje in Mukono District.

In addition, there is a plan to carry out sensitisation and get farmers involved in nursery work to lower the cost because they will be able to obtain the seedlings in their different farm locations.

In Uganda, this technology is used alongside transgenic technology, where genetically modified crops are bred in laboratories by transfer of disease- and pest-resistant genes, which are still at confined field trials.