Uganda develops digital system for fruits, vegetable farmers to boost global competitiveness

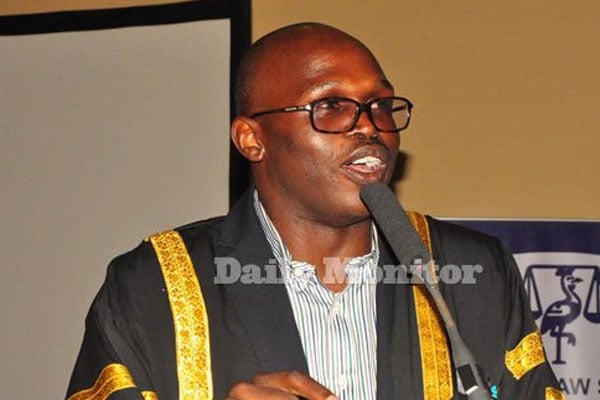

Dr Caroline Nankinga, Assistant Commissioner at Ministry of Agriculture Animal Industry and Fisheries, Department of Crop Inspection and Certification (MAAIF DCIC) addressing journalists on fresh fruits and the vegetable sector in Kampala on September 23, 2024. Photo/Courtesy

What you need to know:

- MAAIF inspectors will access this information in real-time, ensuring compliance with international market requirements before produce reaches Entebbe Airport. In case of interceptions, RUSH's traceability features enable swift identification of the source farm, facilitating corrective action.

Ugandan farmers and exporters have been urged to adopt a new digital traceability system, to enhance the tracking of fresh produce from farms to Entebbe International Airport.

The developers of the system, Re-engineering of Uganda's Sanitary and Phytosanitary Inspection of Horticulture Exports (RUSH), aim to ensure compliance and reduce interceptions that have hindered market access in the past.

According to Dr Caroline Nankinga, Assistant Commissioner of the Department of Crop Inspection and Certification (DCIC) at the Ministry of Agriculture, Animal Industry and Fisheries (MAAIF), agricultural inspectors will only accept commodities processed through the RUSH system starting September 30, 2024.

"Come September 30, the inspectors at the airport are going to just wait on the dashboard to confirm whether the consignment passed through the system before they handle it. It will mean if your consignment has not passed through the system for the airport inspectors to see it on the dashboard, they will not handle it," Dr Nankinga told journalists in Kampala on Monday.

This digital platform transforms manual inspection processes into a real-time, traceable, and streamlined experience. By leveraging technology, farmers and exporters can reduce interceptions, boost profits, and increase their global competitiveness.

Prior to RUSH, manual documentation and inspection processes often led to delays, increasing the risk of interception and losses for exporters. With RUSH, exporters will now upload critical documents, such as farmer information, packing lists, and sorting details, at every stage of the supply chain.

MAAIF inspectors will access this information in real-time, ensuring compliance with international market requirements before produce reaches Entebbe Airport. In case of interceptions, RUSH's traceability features enable swift identification of the source farm, facilitating corrective action.

Mr Samuel Balagadde, chairperson Hortifresh said the key reasons for the interceptions include "harmful organisms like pests, chemical residues, and documentation errors. These issues have affected a range of crops, including capsicums, hot peppers, garden eggs, Karella, and soursop, among others." However, he added that HortiFresh with its partners are working on various interventions to ensure that these issues are addressed and mitigated across the value chain.

Ms Maria Bisamaza, Manager for Quality and Standards at the Presidential Advisory Committee on Exports and Industrial Development (PACEID) said, "to be intercepted is a very bad sign and it will come at cost."

PACEID is working on the food safety law “Food and Regulatory Authority” whose bill has been drafted and waiting for few stakeholders’ inputs to be introduced in the cabinet.

The said the Food and Regulatory Authority aims to address issues of standards, agrochemical regulations, food safety, inspections among others which are key challenging factors of food exports from Uganda.