Prime

Mobile juicer gives hope to Acholi fruit farmers

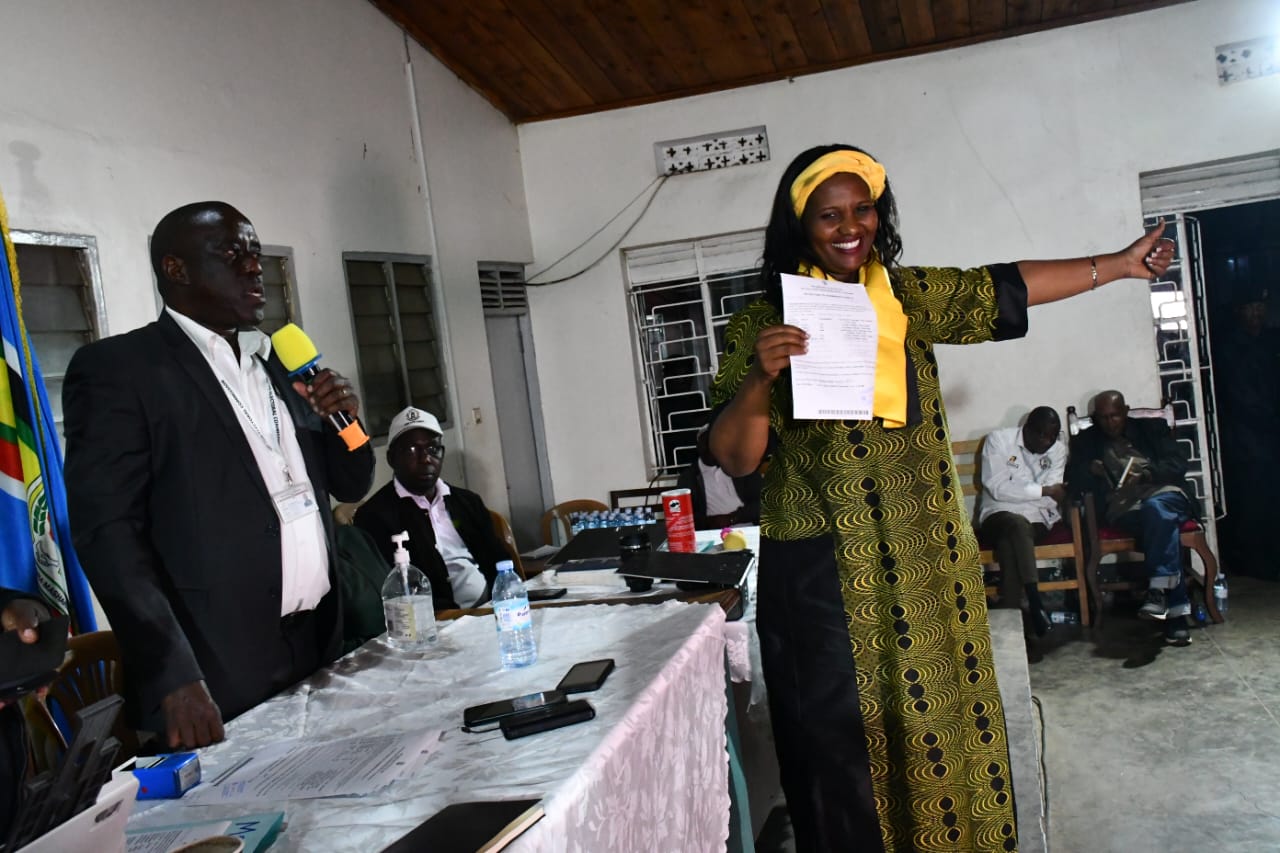

A man washes mangoes to feed into the juice processor at Gulu University on Monday. PHOTO/CAROLINE AYUGI.

What you need to know:

- With the juicer, farmers are now earning Shs200 per kilogramme of their mangoes.

- 637 sold: The litres of mango juice that Gulu University has so far sold.

A recent technology by Gulu University that processes ready-to-drink juice on a mobile truck could give hope to thousands of fruit farmers in the Acholi Sub-region who have struggled to find market for their fruits.

For the past five years, farmers in Acholi Sub-region have been grappling with lack of market for their fruits, especially mangoes and oranges, following intensified fruit growing under the Operation Wealth Creation (OWC) programme.

However, on June 5, the university’s Faculty of Agriculture with support from OWC acquired a mobile multi million mango juice processor that processes five tonnes of juice daily,.

Dr Collins Okello, the Dean of Faculty of Agriculture, on Wednesday said they are looking for bulk juice buyers since their production is industrial.

“The pulp we are producing is for the industrial market but the buyers we have are packaging it for resell or home consumption. We have some prospects of bulk buyers but they are yet to confirm their commitment,” Dr Okello said.

He added that farmers are receiving Shs200 per kilogramme of mangoes they are selling to the university.

When this reporter visited the university’s faculty of Agriculture where the machine is currently stationed, operators were washing fruits and loading them into the crushers while others were assisting farmers to weigh their produce on digital scales.

The faculty records indicate that by Sunday evening, 31.2 tonnes of fresh mango fruits had been bought from farmers and 10.2tonnes of juice processed from it.

Ms Irene Akite, a staff at the faculty and also the sales and marketing officer for the project, revealed that a litre of juice is at Shs4,000.

“We have sold 637 litres of the processed mango juice to local buyers and retailers in Gulu City and earned Shs2.66m,” she said.

She added that incase the juice comes out sour they turn it into wine.

“We have that category of unpreserved pulp and it easily goes bad, so we process ingredients to turn it into wine,” she added.

Challenges

The university administration revealed that they are yet to get an industrial market for the 10 tonnes of mango pulp that were processed in two weeks ago.

Dr Okello said due to lack adequate storage in the cold room they have resorted to preserving some of the pulp.

“The cold room can store about 800kg sbut it is now full, so whatever we are processing now is being preserved to extend the shelf life,” he revealed.

Dr Okello explained that processing of the mango pulp is a commercial experiment that will stop once the mango season ends.

“We know there are a lot of local mangoes that get spoiled. So, we wanted to know if it is viable for us to make juice out of these mangoes,” he said.

He added that they would send a report to government on the viability of the investment.

Dr Okello revealed that some of the challenges being experienced would be sorted after setting up a factory.

“This trial will inform what kind of storage, waste management facility and how much mangoes we need to set up a fully-fledged factory,” he said.